How to Make St. Louis-Style Frozen Pizza in 7 Steps

Making St. Louis-style frozen pizza is a beautiful fusing of science and art. Each day we manage to make 3,000 frozen pizzas, all by hand. That’s upwards of 60,000 pizzas a month delivered only to local, St. Louis-area stores. So how do we do it? Why, one step at a time, of course. Here’s how it all goes down when we make St. Louis-style frozen pizza just the way you love it:

1. Daily Crust Delivery

They don’t call bread the “staff of life” for nothing. Dogtown Pizza would be nothing without its signature St. Louis-style crusts. Our iconic cracker-like crusts are the work of hard working bakers in the new Dogtown Pizza Bakery. The bakery delivers fresh, still-warm-from-the-oven crusts every day so we can get to work. The smell of fresh pizza crust is beyond wonderful. If we could bottle that smell and give it to you, we totally would.

2. Prep Work

Remember the whole “made by hand” thing? This extends to the prep work we do before the pizzas are even made. We have DTP team members skillfully chopping veggies like onions and peppers as well as fresh herbs like basil. They do it at a rapid-fire pace and with the precision of ninjas. It’s impressive, really.

3. Assembly Time

Time to build the pizzas! At Dogtown Pizza, we have four production tables all going at the same time making 20 pizzas at a time. This step has four steps within itself:

- Lay out the cardboard backing and then the crusts.

- Dole out our special recipe pizza sauce. This happens in a graceful swirling motion, starting at the middle of the crust and moving outward.

- Sprinkle on the cheese. Handfuls of our special blend of mozzarella, provolone, Swiss, and cheddar are sprinkled–nay–rained down over the sauce for optimal gooeyness.

- Lay on the toppings. Ah yes, the toppings. Pepperoni, Sausage, Hot Wing Chicken, Veggie, Tomato Basil Garlic…we heap on the toppings from edge to edge so you get a mouthful of delicious flavor no matter what piece of the pie you get.

It all goes by so fast, it’s like one big, pizza-making blur.

4. Quality Control

Quality control is one of the most crucial steps needed to make St. Louis-style frozen pizza. After the pizzas are made, we inspect each one – hardcore. This means that every pizza has to have the correct amount of toppings (20 pepperonis, anyone?), the correct portion of cheese and the accurate smothering of sauce. If something is even slightly askew, we send it back. SEND IT BACK, DARN IT.

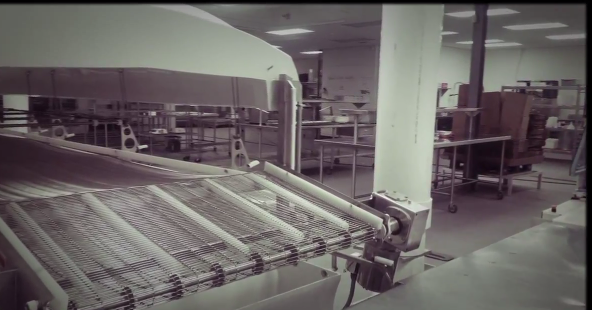

5. Flash Freezing

Flash freezing is the crux of our entire operation. It makes sure that all those fresh, local ingredients TASTE that way by the time you bake your pizza in your home. Flash freezing also ensures that you can taste all that love and devotion we pour into our pizzas. That’s not weird is it?

Thanks to our new flash freezer (which we installed back in May) it takes only two minutes to freeze a pizza. This ensures that your pizza will be as fresh as the day it was made.

6. Shrink Wrapping

After the freezing process, we shrink wrap the pizzas to prolong the freshness. It also keeps any air or outside elements where they belong – no where near your pizza – and keeps the toppings in place without flattening them.

7. Deep Freezing

After labeling and packaging the pizzas, we store them in -10° deep freezer before shippin’ time!

The final step required to make St. Louis-style frozen pizza is actually its un-making: take it, bake it, and eat it! You can find Dogtown Pizza in every major St. Louis grocery store including Target, Wal- Mart, and Walgreens. Pick up your favorite Dogtown Pizza variety today!